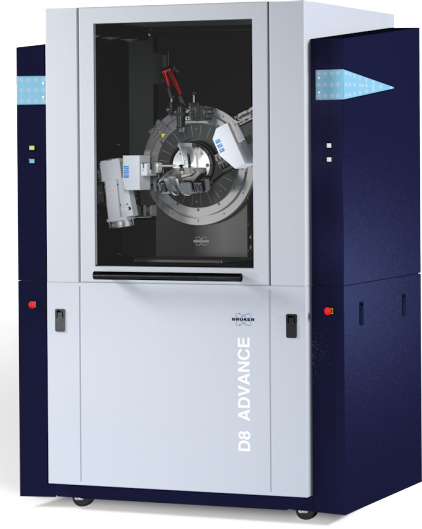

Supported by the domestic and international industry partners and government agencies, such as Mitacs, Canada Foundation for Innovation, and the Natural Sciences and Engineering Research Council, the HPPM lab has been fully equipped to produce (cast and/or sinter), test, and analyze a wide variety of metallic materials. The on-site casting lab allows for production of permanent and sand mold castings which can be subjected to a number of custom or commercial heat treatments. Further, Dr. Sediako’s state-of-the-art material test system is capable of conducting complex fitness-for-service tests (tensile, staircase/multistep creep, and thermo-mechanical fatigue) up to ~1000 °C. The HPPM lab can perform thermal, phase, and metallographic analyses using optical microscope, scanning electron microscope, energy dispersive X-ray spectroscope, differential scanning calorimeter, and an X-ray diffractometer and lab’s access to the international neutron diffraction facilities.

Some of the manufacturing, testing, and analytical equipment that HPPM is using in its research is owned by the UBC Okanagan School of Engineering (https://engineering.ok.ubc.ca/), FiILTER lab (https://www.filterubco.ca/), CleanTech Hub (https://cleantech.ok.ubc.ca), and Dr. Bichler Laboratory (https://bichler.ok.ubc.ca/material-science-home-page/facilities/).

Hydrogen Embrittlement Characterization

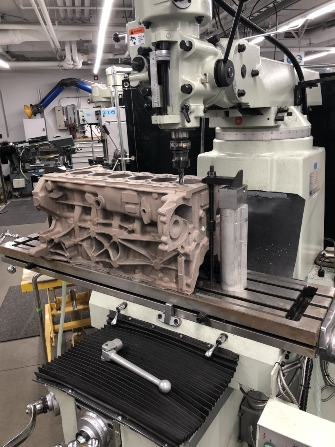

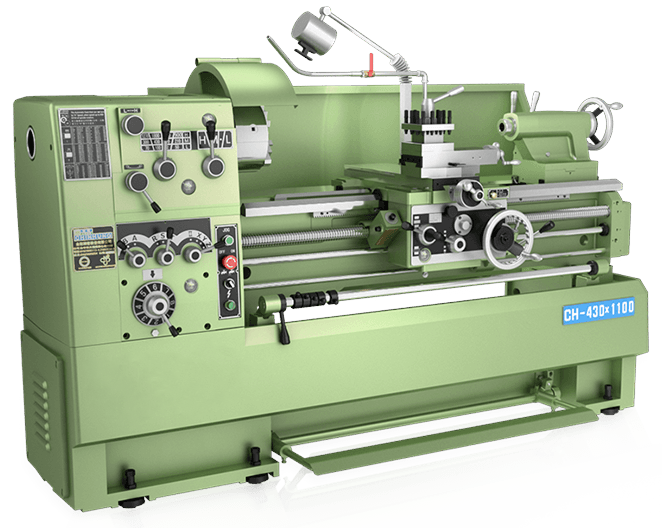

Manufacturing

Casting

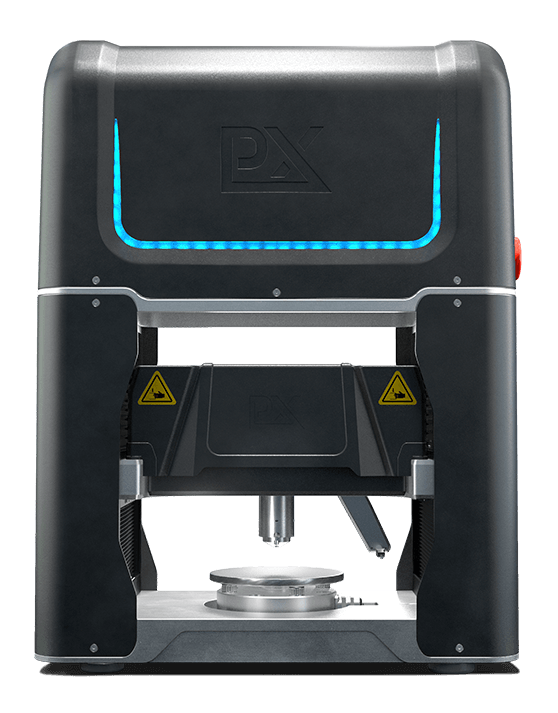

Mechanical Testing

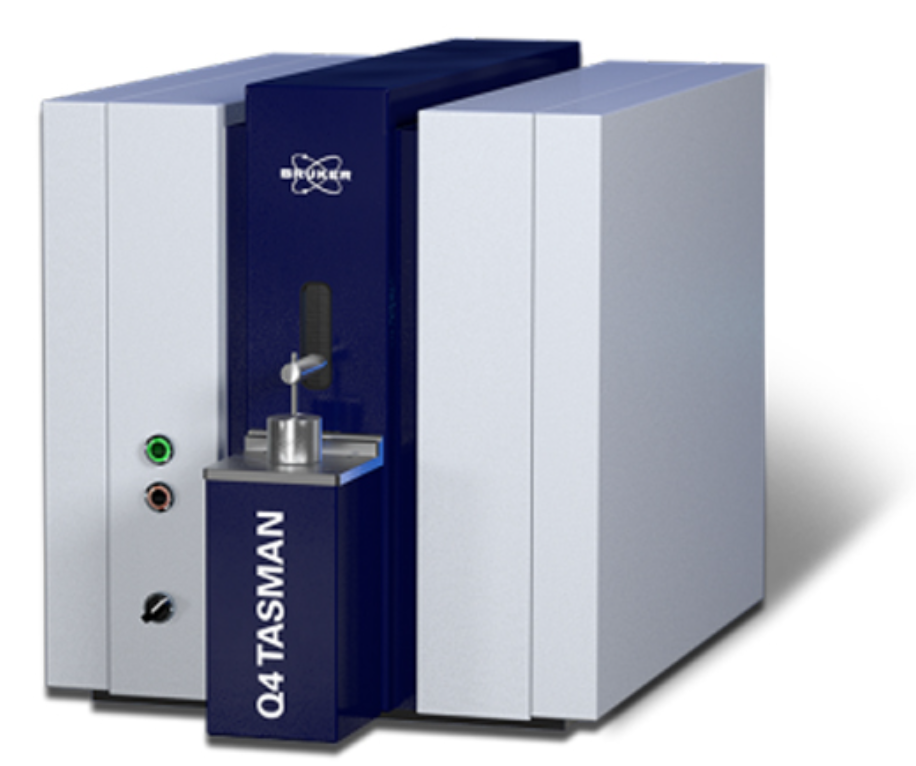

Material Characterization

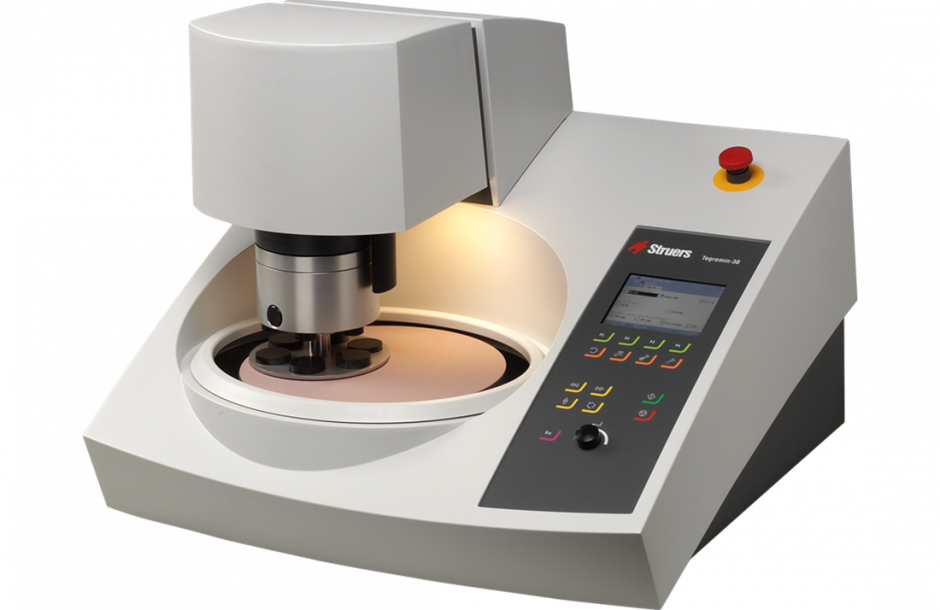

Sample Preparation