Effects of hydrogen embrittlement on CSA Z245.1 Grade 290 and API 5L X60 Pipeline Steels

Lead Researchers: Rashiga Wallalawita, Matthew Hinchliff

A major challenge with hydrogen transportation is its propensity to diffuse into metals and the resulting negative effects it can have on their mechanical properties. One well-known hydrogen-induced phenomenon is hydrogen embrittlement (HE); a type of hydrogen damage that reduces the ductility, fatigue life, and fracture toughness of metallic materials. The extent to which hydrogen damages a material is unique based on its chemical composition, microstructure, and environmental conditions to which it is exposed.

This study aims to determine the susceptibility of common pipeline materials to hydrogen embrittlement in a range of loading conditions, and hydrogen concentrations using a custom autoclave for in-situ mechanical testing in gaseous hydrogen. The results of this study are fundamental to the development of Canadian codes and standards for gaseous hydrogen handling in pipelines.

Throughout this project, researchers from the High Performance Powertrain Materials Laboratory have developed a number of custom setups to enable in-situ material testing in high-pressure gas. These setups include an in-house developed gas management system, in-situ autoclave, and hollow specimen testing infrastructure. The development of these setups has enabled the characterization of hydrogen embrittlement of many materials while exposed to representative service conditions.

Effects of hydrogen embrittlement in Al alloy used in engine blocks

Lead Researchers: Rashiga Wallalawita

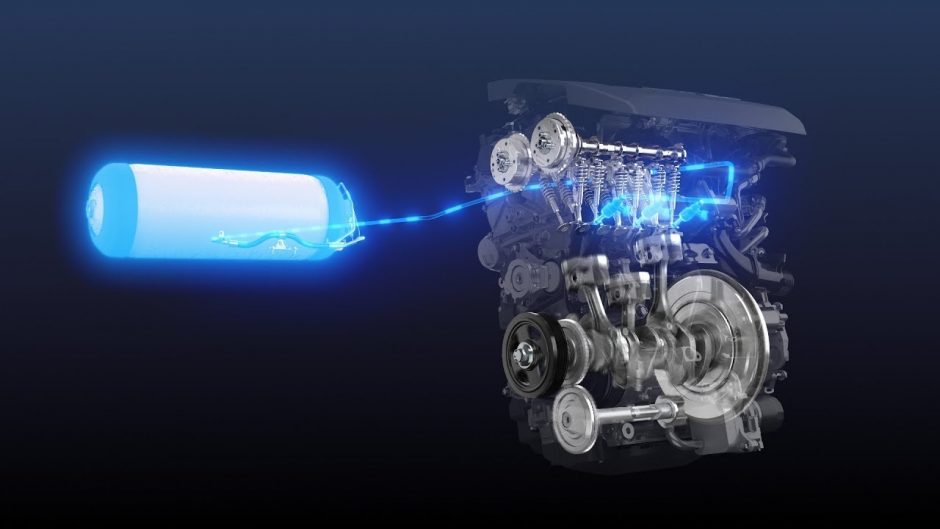

Hydrogen internal combustion engine vehicle (HICEV) is considered to be a near emission-free method of transportation and has been heavily researched. Considering the strict emission requirements it is believed that a portion of future automobiles will be HICEVs.

Furthermore, with the current industry trend towards liner-less aluminum engine blocks, It is important to investigate the effect of hydrogen embrittlement on automotive aluminum alloys which are used for engine blocks.

The experiments required for this study are conducted at the newly constructed Hydrogen lab in UBCO.

Effects of blended hydrogen enriched natural gas on the microstructure and mechanical properties of a x42 steel pipeline and grade 290 weld

Lead Researcher: Austin Piche

Investigated the effects of hydrogen-enriched natural (HENG) blend on the microstructure and mechanical properties of an API 5L X42 pipeline for FortisBC. Tested and analyzed the ultimate tensile strength, yield strength, percent elongation, area reduction, fracture surface, microhardness, and phase compositions of the X42 through tensile tests, Vickers hardness testing and scanning electron microscope. These tests were conducted on the pipeline material both before and after exposure to the HENG at concentrations of 0%, 5%, and 20% for prolonged times in an enriched environment of 2 weeks, 2 months, and 6 months.

.