Microstructural and Tribological Characterization of Electrolytic Jet Plasma Oxidation (EJPO) coating for high tempemperature applications

Lead Researcher: Nasim Bahramian

Nowadays, there has been a growing trend toward manufacturing linerless engine blocks with advanced coating materials as alternatives to the Fe liners. These coatings are to possess specific characteristics to protect the Al part from the severe conditions in the combustion chamber. For instance, high tribological

performance in terms of friction, wear, and oil retention (the ability of the surface to retain oil in its open porosities to prevent scuffing phenomena) is necessary for engine block’s coating. Furthermore, an acceptable amount of thermal conductivity is required to prevent local overheating of the Al block.

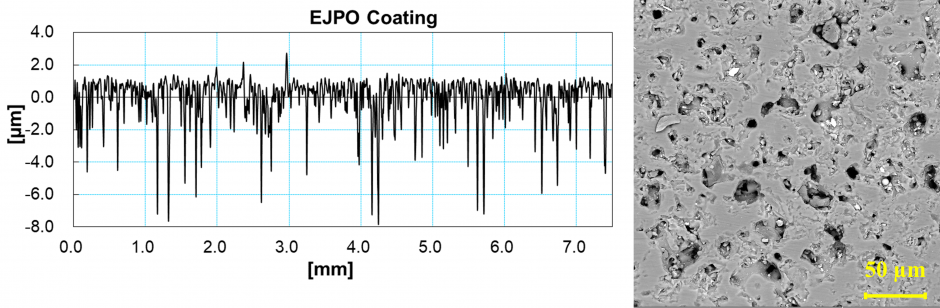

At UBCO, we work on an engine block coating called Electrolytic Jet Plasma Oxidation (EJPO). EJPO is a plasma-assisted coating generated by electrochemical conversion of the lightweight metal surface to a hard ceramic film. In order to characterize this ceramic coating, the surface roughness and theoretical oil retention have been measured (Ra ~ 0.8 µm). A tribometer has been designed and manufactured to do friction and wear tests at different lubrication conditions. Further, critical mechanical properties for cylinder block’s coating like micro-hardness and thermophysical properties like thermal conductivity are planned to be measured.

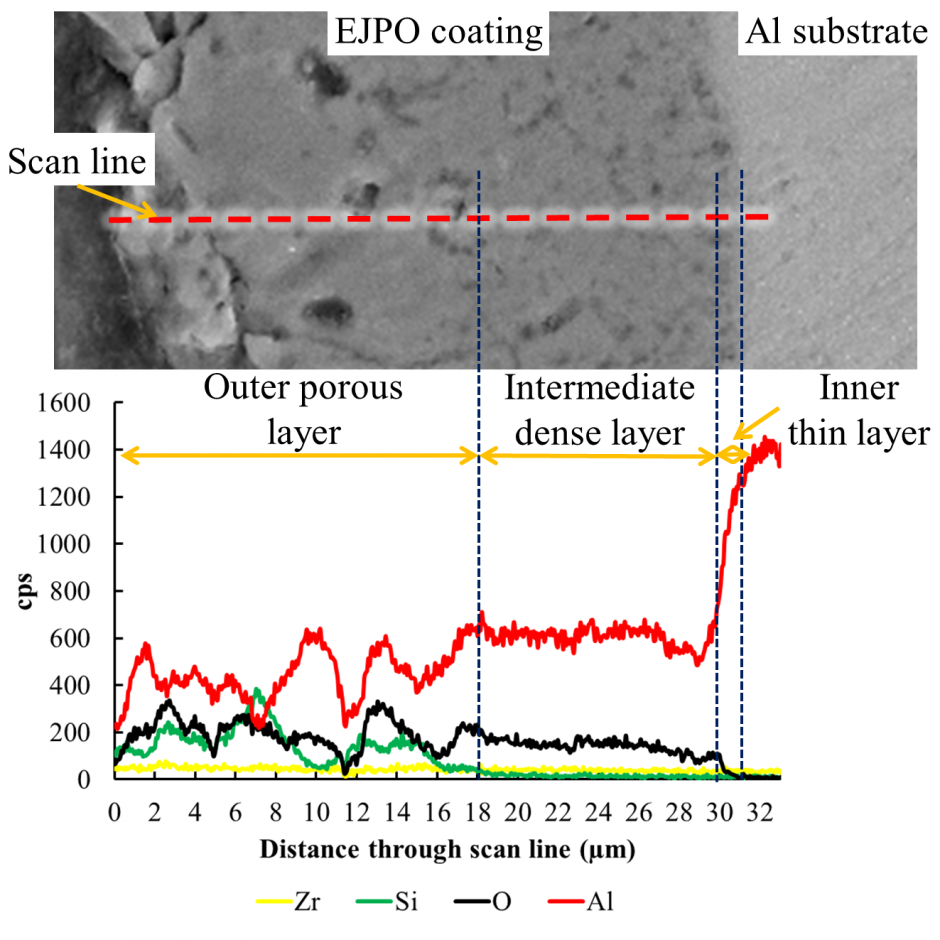

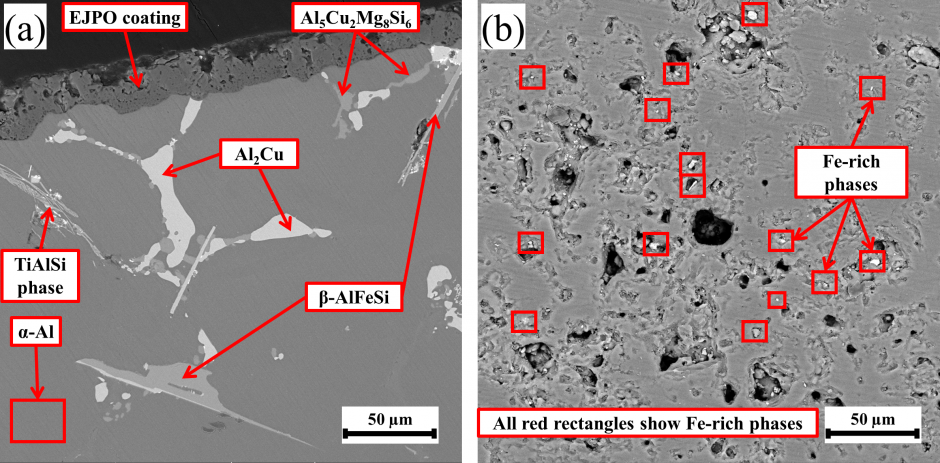

In terms of microstructural analysis, SEM observations of the EJPO cross-section indicate that the coating consists of three layers. The outer layer is subjected to a high cooling rate and rapid solidification, leading to having a porous amorphous structure. The intermediate layer is dense and improves the coating’s thermal conductivity capability. There is a thin alumina film, about 1 µm, in the interface of the coating/substrate. The roughness patterns of the EJPO coating and some SEM micrographs are shown in the images below.

Publication:

N. Bahramian, S. Kianfar, J. Stroh, D. Sediako, J. Tjong. “An investigation of the microstructure and oil retention of Electrolyte Jet Plasma Oxidation (EJPO) coating”, Advances in Surface Engineering, 2022 (accepted)

FE modeling of residual stress developed in Al engine blocks subjected to PTWA and EJPO coatings

Lead Researcher: Rashiga Walallawita

In order to meet the strict emission standards, automotive manufacturers are continuously searching for ways to reduce weight and improve performance. Due to this reasoning engine blocks have evolved from cast iron (Fe) engine blocks to Al alloy engine blocks with Fe liners. However, due to the mismatch of thermal expansion coefficient between Al and Fe, high residual stresses occur in the casting process. These residual stresses cause the engines to fail prematurely. In order to combat this, attention has been given to develop Al alloy engine blocks with advanced surface coatings (engine cylinder).

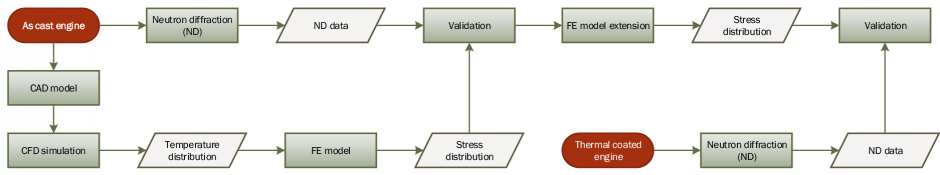

Even though Fe liners are removed from the engine block still, residual stresses are induced due to the thermal gradients while casting. Furthermore, due to the thermal coating process, the induced thermal stresses can further change. Therefore, in this research, a Finite Element model is developed to simulate the change in residual due to thermal coating. The overview of the project is illustrated in Figure 1.